An increasing number of STEM professionals have been flooding the market for the last decade, yet in the next ten years there will be a shortage of professionals in the field. The U.S. Bureau of Labor Statistics estimates that from 2012 to 2022, STEM employment rates will grow by 13%, higher than the 11% projected growth across all other occupations. And yet by 2025, the U.S. will need approximately one million more professionals than it will have produced.

Engineers Week is one step towards a solution to this conundrum. The 66th Engineers Week, which started on February 19th, is being celebrated in schools across the nation. With new initiatives such as the Future Cities Project and Girl Day, Engineers Week aims to inspire the next generation of engineers who will help steer the U.S. as a global leader in the fields of science, technology, engineering, and mathematics. Below you will see a number of academic infographics that showcase how the future generation of engineers can impact the world.

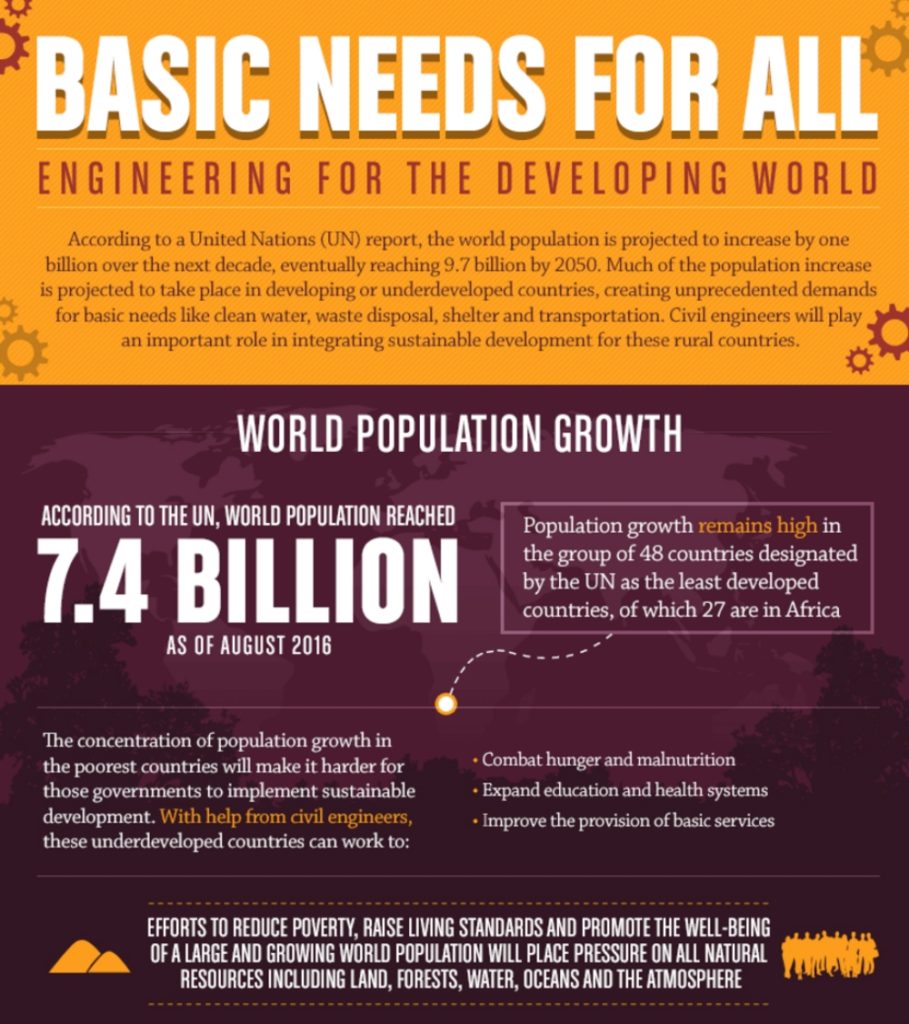

From 7.4 billion in 2016 to 9.7 billion in 2050, the world's population will continue to grow over the next decade, and the brunt of the baby boom will be centered around developing countries. The problem is that these same regions do not have sufficient infrastructure to cope with the rapid growth.

The challenge to bring basic infrastructure to the developing world now falls on the shoulders of the next generations of engineers. By having a STEM expertise, it will not only put them in the forefront of science and technology, but it provide them with the skills to steer the world towards a better future. To learn more about engineering infrastructure for the developing world, check out the infographic below created by Norwich University’s Online Master in Civil Engineering program.

Technological advances in transportation and information technology have resulted in a global tourism boom in recent years. The good news: the economies of both leading and emerging destinations have been positively impacted. The bad news: the rise in coastal tourism is taking a toll on the environment. The silver lining: the continuing surge in global coastal tourism has indirectly caused more demand for environmental engineering professionals.

Indeed, the next generations of environmental engineers will have to propose and develop sustainable coastal tourism solutions that aren't focused on doing the tourists a favor — they're literally saving the planet, one tourist destination, coast, and reef at a time. To learn more about how engineers can help build sustainable coastal tourism, check out this infographic below created by Ohio University’s Online Master of Science in Civil Engineering program.

Modern communication technology is one of the most promising fields of the future. From homing pigeons to telegraphs to status updates, the advances in modern communication have supported the advance of civilization for ages. At the heart of it all, electrical engineers are solving the real world problems that allow these communication technologies to function and progress.

What's next for the electrical engineers of the future? Will virtual and augmented reality communication be commonplace? Will the Internet of Things take over?

Electrical engineering has never been as game-changing a field as it is today. To learn more about electrical engineering's impact on communication, check out this infographic created by the New Jersey Institute of Technology’s Masters in Electrical Engineering program.

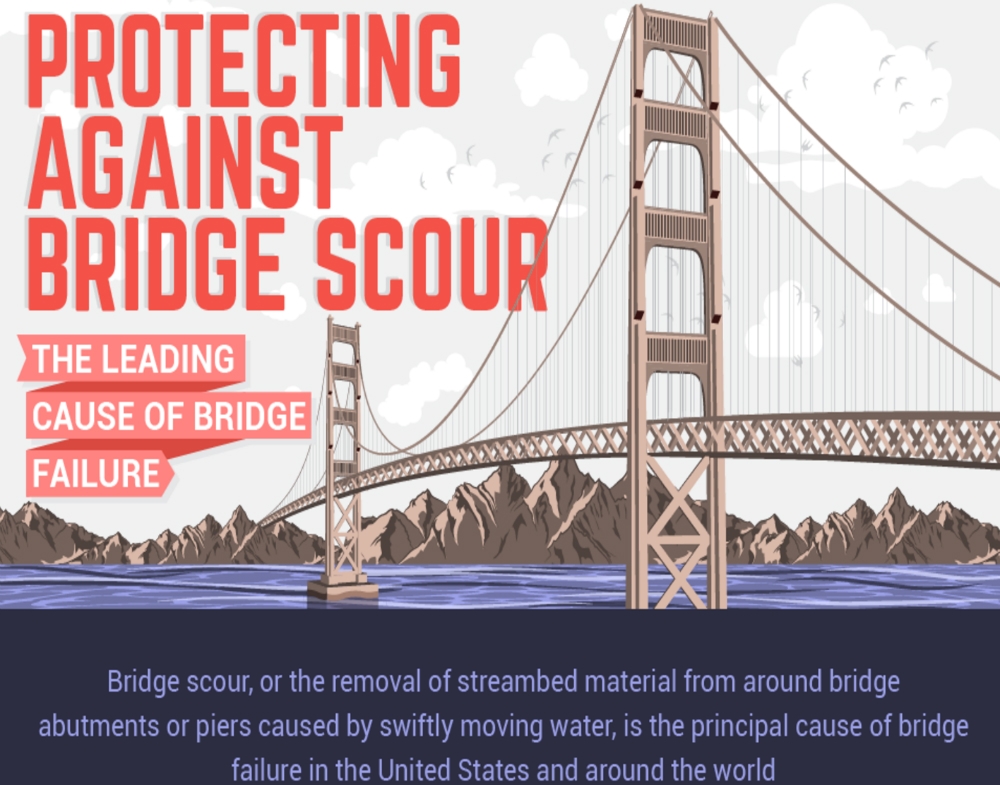

Roads, bridges, and other critical infrastructures are the hallmarks of modern civilization. The bridges of today are not only a testament to the cultural aesthetics and norms of the period, but also the technological prowess of society.

However many of our bridges are crumbling and scouring due to several causes. We need a new generation of engineers to not only preserve the architectural symbols of our culture, but also adopt a modern approach to the renovation of existing bridges and planning of new ones. These engineers are ensuring the safety of the people using the infrastructure today and a century from now. To learn more about engineering strategies that prevent bridge failure, checkout the infographic below created by the New Jersey Institute of Technology’s Master of Science in Civil Engineering Online program.

– by Austin Anderson, Circa Interactive